The robot-remover is intended for removal of plastic details from TPA. The robot can perform translational movements along three axes and rotate the working body along the Z axis.

The main task that stood at the forefront was the development of a simple and inexpensive manipulative robot, at the same time functional and fault-tolerant.

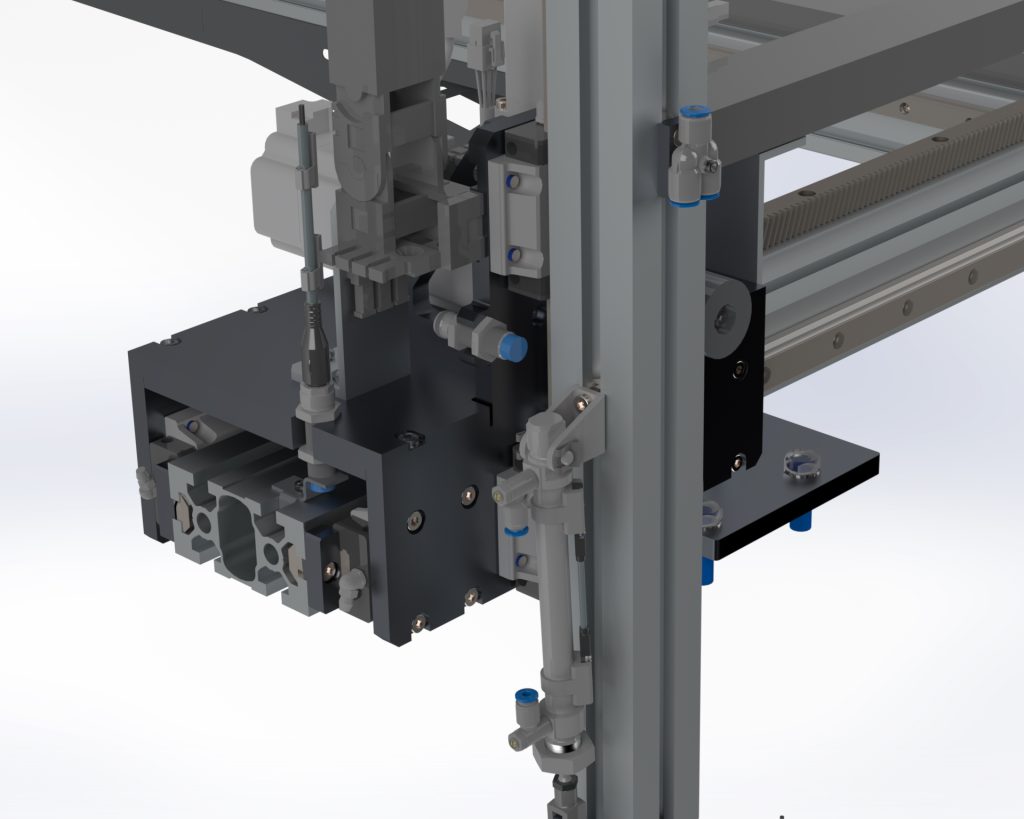

Given the fact that the robot was needed for our own production of injection molding machines and the required number was small (7 machines), I used an aluminum structural profile as a frame. Delta motors were used as a drive. Thanks to the high-precision guides and rack gears from HIWIN, the robot works with an accuracy of 0.1mm.

Thanks to the use of vacuum systems from FESTO, the robot was able to work with parts up to 4kg.

Automation of production processes is one of the main ways to increase the efficiency of the company and reduce the cost of products. Industrial robots play a key role in automation.

The use of industrial robots and manipulators makes it possible to relieve personnel from heavy and monotonous technological operations, achieve a high degree of standardization of products, increase productivity and improve product quality.